NOX REDUCTION

Selective Catalytic Reduction

Providing SCR Systems Since 1982

- Over 130 systems

- Notable Firsts

- First SCR on a US Coal Fired Boiler (Carney’s Point 1993)

- First SCR on a 100% Petcoke Fired Boiler (Deepwater 2006)

- Designing SCRs for new utility boilers firing a wide range of fuels

- Currently executing retrofits worldwide

Our Selective Catalytic Reduction (SCR) technology is proven worldwide in installations firing a range of fuels including oil, gas, and solids for a variety of applications from large-scale pulverized coal (PC) utility boilers, to industrial process heaters and boilers, to combustion turbines. We supplied the first four SCR systems on utility plants in the United States, complementing our extensive global experience. We provide turn-key services including design, supply, erection, and start-up for the most complex installations.

- Proven design is simple, reliable and robust

- Integrated Ammonia Injection System - needs no tuning

- In house CFD flow modeling for improved gas distribution, pressure drop, and reagent utilization

- Low maintenance labor and material costs

Applications

Power Plants

Coal

Pet Coke

Lignite

Oil

Gas Turbines

Simple Cycle

HRSG

Miscellaneous

Biomass / Co-firing

Packaged Boilers

Chemical Processes (e.g. Fluidized Catalytic Cracker Off Gas)

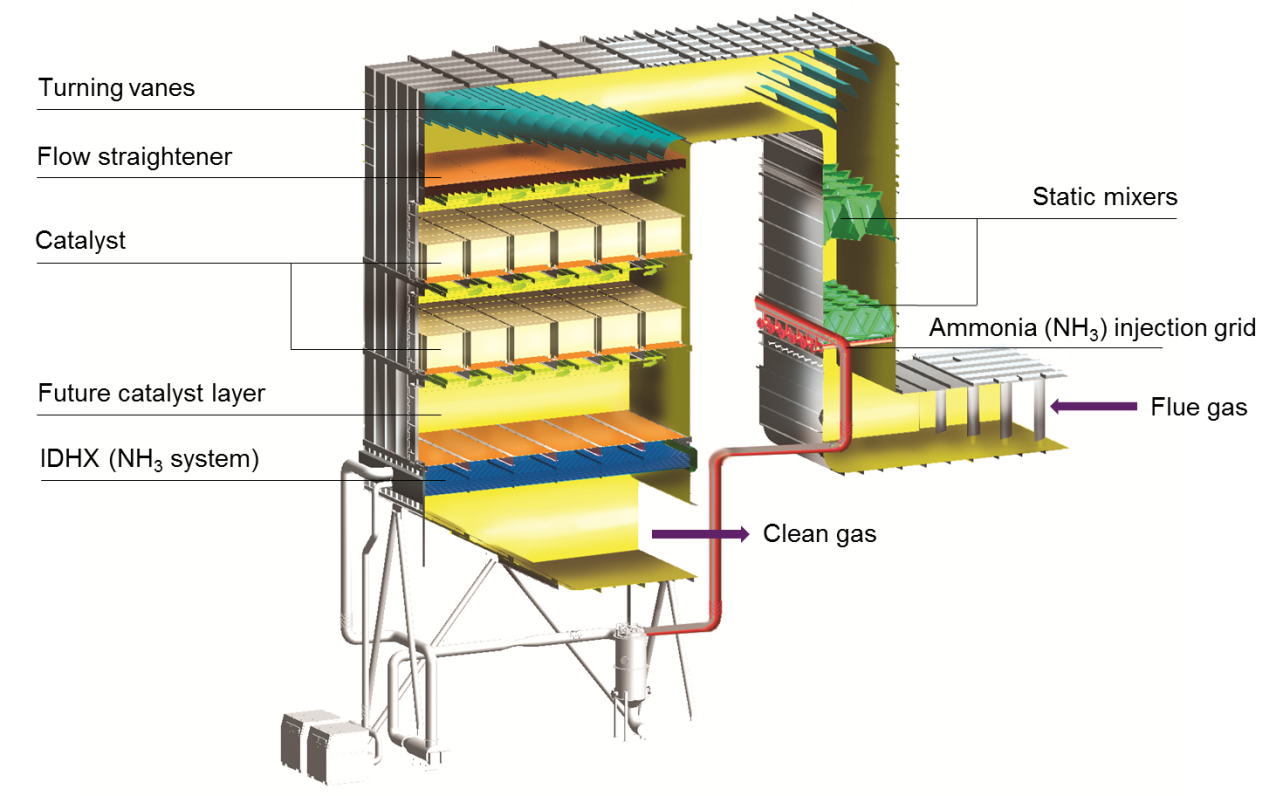

How it Works

- Selective Catalytic Reduction (SCR) technology is designed to provide reliable high removal rates of NOX

- The SCR system is comprised of three main parts, ammonia supply, ammonia injection and catalyst.

- Ammonia injection comprises an injection grid and static mixer combination.

- Patented In Duct Heat Exchanger (IDHX) for efficiency

- Flow models are performed to validate the layout and ensure good performance of the system

- Flow is corrected with straighteners and turning vanes.

Special Features

Integrated Ammonia Injection Grid (AIG) and Mixer design

- Proven design for difficult applications

- No tuning

- Improved Mixing for Temperature

- Minimizes impact of combustion issues

- Able to achieve stringent RMS distribution requirements

- Optimized to simultaneously achieve required distribution at low pressure drops

Continuously Improving the technology

- In duct heat exchanger for NH4OH vaporization (U.S. patent 5296206)

- Feed-forward/feed-back control logic (U.S. patent 5047220)

- Simplified catalyst loading/unloading system

- Economizer bypass for low load operation

- Aqueous ammonia stripper (patent pending)

- Special method for cooling flue gas temperature (patent pending)

Modular Approach to Design

- Early constructability

- Review worksite logistics and establish innovative methods of construction

- Evaluate possibilities to maximize pre-fabrication – both off and on-site

- Evaluate hauling / rigging / equipment / access

- Evaluate field labor savings relative to design and constructability

- Utilize computer modeling in construction activity

Typical Project

- To comply with Europe’s Industrial Emission Directive, TSE awarded a contract to retrofit a selective catalytic reduction (SCR) system to their 125 MWe (315 MWth) coal and biomass unit #3 in Naantali Finland.

- The project scope includes the design, supply, erection and commission of a new selective catalytic reduction reactor with catalyst and steel structures, an ammonia water-storing, unloading, injection and distribution system, as well as, flue gas ducts and new induced draft fans.

Talk with a technical specialist

Your questions are our priority. For general inquiries please add your question below and we’ll be in touch.

For spare parts inquires please email us directly at spareparts@woodplc.com, please include the part number and serial / job number with your inquiry.